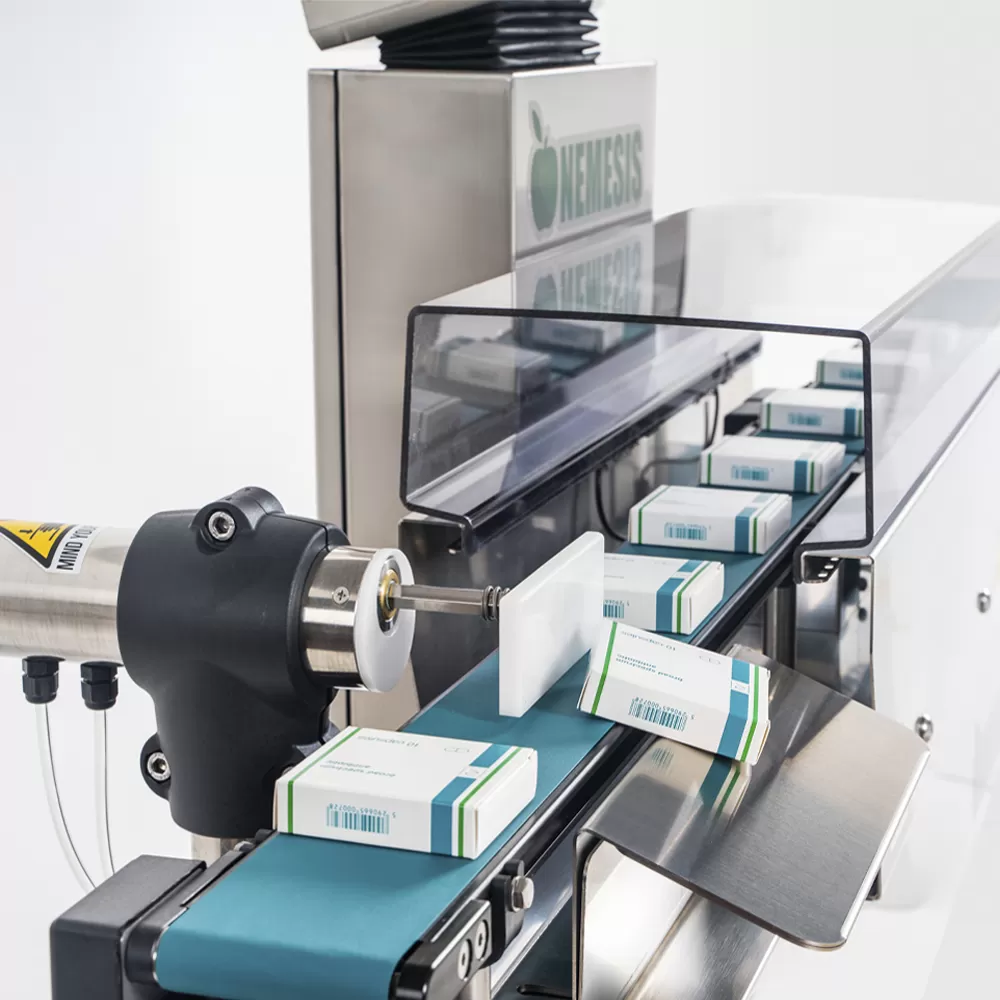

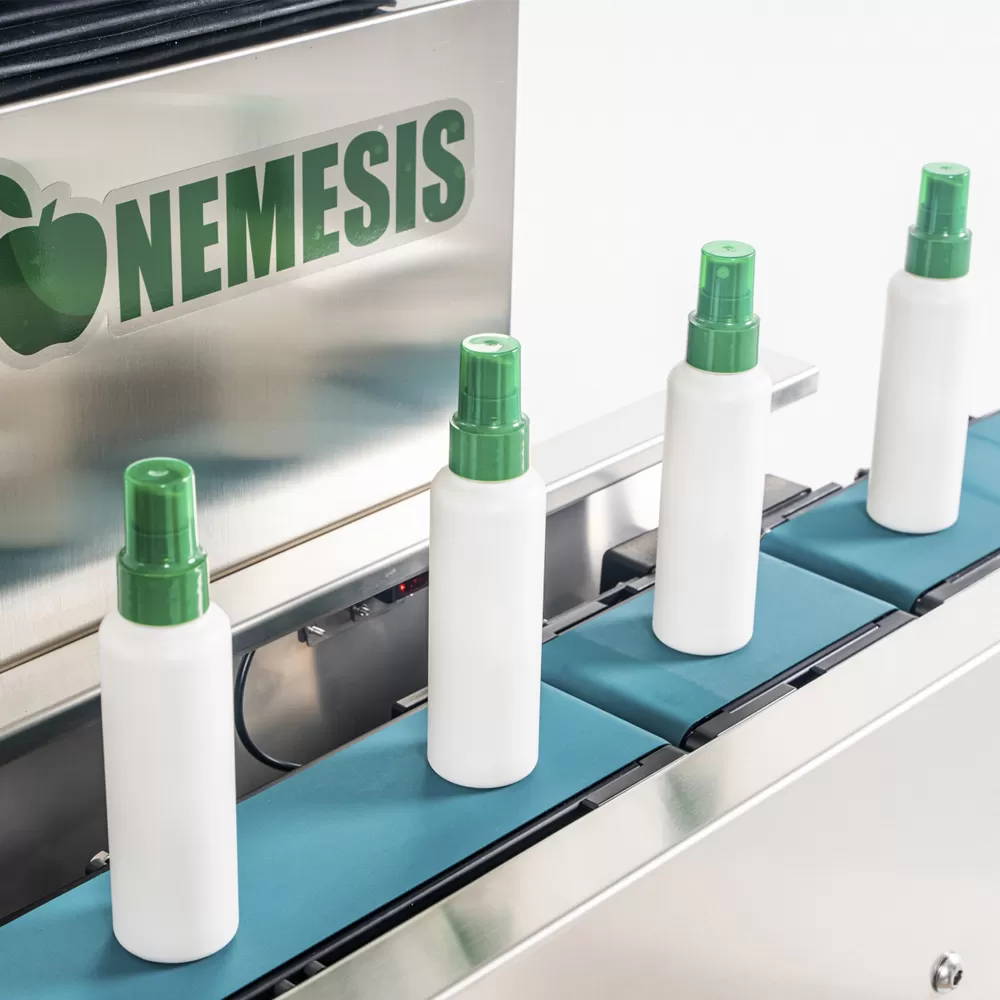

Checkweighers

S Series

The lightweights specialist

From 1 g to 600 g - Maximus throughput 600 ppm

Featuring a weighing accuracy up to ± 0,005 g, still ensuring the highest speed, it's ideal for the pharma industry with light and small products.

It complies with Good Manufacturing Practice (GMP) requirements for pharmaceutical production and the strictest quality control standards in the industry.

It can be integrated with one- or two-dimensional marking systems, display system for monitoring the package and multiple ejector systems.

Download the catalogue

From 1 g to 600 g - Maximus throughput 600 ppm

Featuring a weighing accuracy up to ± 0,005 g, still ensuring the highest speed, it's ideal for the pharma industry with light and small products.

It complies with Good Manufacturing Practice (GMP) requirements for pharmaceutical production and the strictest quality control standards in the industry.

It can be integrated with one- or two-dimensional marking systems, display system for monitoring the package and multiple ejector systems.