THE CHALLENGE

Nemesis designed and built a customized solution for a French client, a biscuit and pastry manufacturer. The checkweigher was intended for weighing shaped dough balls within their production facility, which already housed large and complex machinery such as mixers, shapers, and long conveyors.

The project presented significant design constraints; the machine had to be tailor-made to seamlessly integrate into the existing setup with precise entry and exit points for the dough.

Moreover, the dough was highly moist and soft, prone to sticking to any surface. The weight could vary from 1000 to 3000 g depending on the production batch and couldn't be rejected using air jets, typically used for lightweight products.

The required scale interval was 1 g.

Architecture completely tailored to the existing production line

The conveyors were designed and built to the necessary length to receive the product at a precise point in the line, weigh it, and transport it to the inside of the packaging machine.

The machine's platform height, conveyor width, and length were specifically studied to integrate seamlessly into the existing production system, fully respecting pitch requirements and functionality.

V-shaped entry conveyor

To receive the dough released from the overhead mixer onto the weighing machine, this V-shaped entry conveyor was designed to collect and correctly convey the product to the weighing conveyor.

Drop-down ejection system

To reject, in case of weight non-compliance, a heavy product that is also soft and delicate, we couldn't use air jets as they are insufficient for the weight, but pneumatic pushers would also damage the product.

Therefore, Nemesis decided to adopt this drop-down rejection device, in which the exit conveyor lowers via a pneumatic command to drop the non-compliant product into a collection basket.

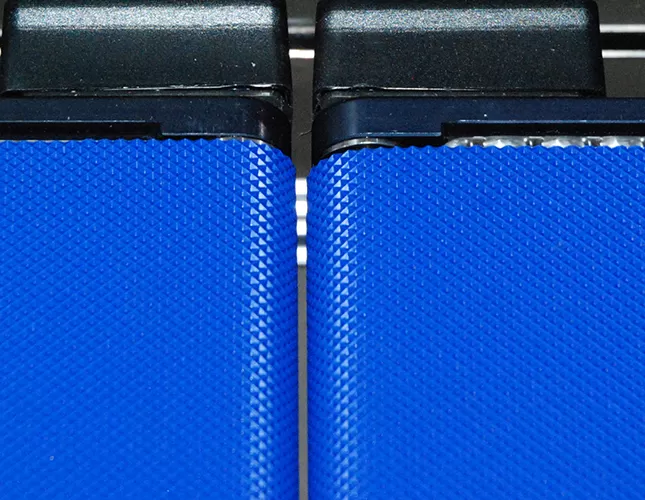

Special belts for moist food

The extremely moist and soft nature of the product to be handled required the study and identification of special belts with a weave designed to prevent the dough from sticking to the conveyor belt. These belts are made of food-grade material with high washability.

For this purpose, the entire machine has been built with an IP66 protection rating, meaning it is entirely made of stainless steel and perfectly sealed in all its assemblies to be washed with powerful water jets.

THE BENEFITS

- No need to modify the production system

- The molded dough balls slide without friction and without damaging the belts

- The architecture designed to measure the entry, exit, and reject belts allows precise conveyance of the product to downstream production machines.

- The out-of-weight doughs are gently rejected without damage and can be easily reprocessed

- The use of stainless steel ensures smooth surfaces that minimize bacterial contamination

- The special structure of the machine and its components can be washed with powerful water jets for thorough sanitation.