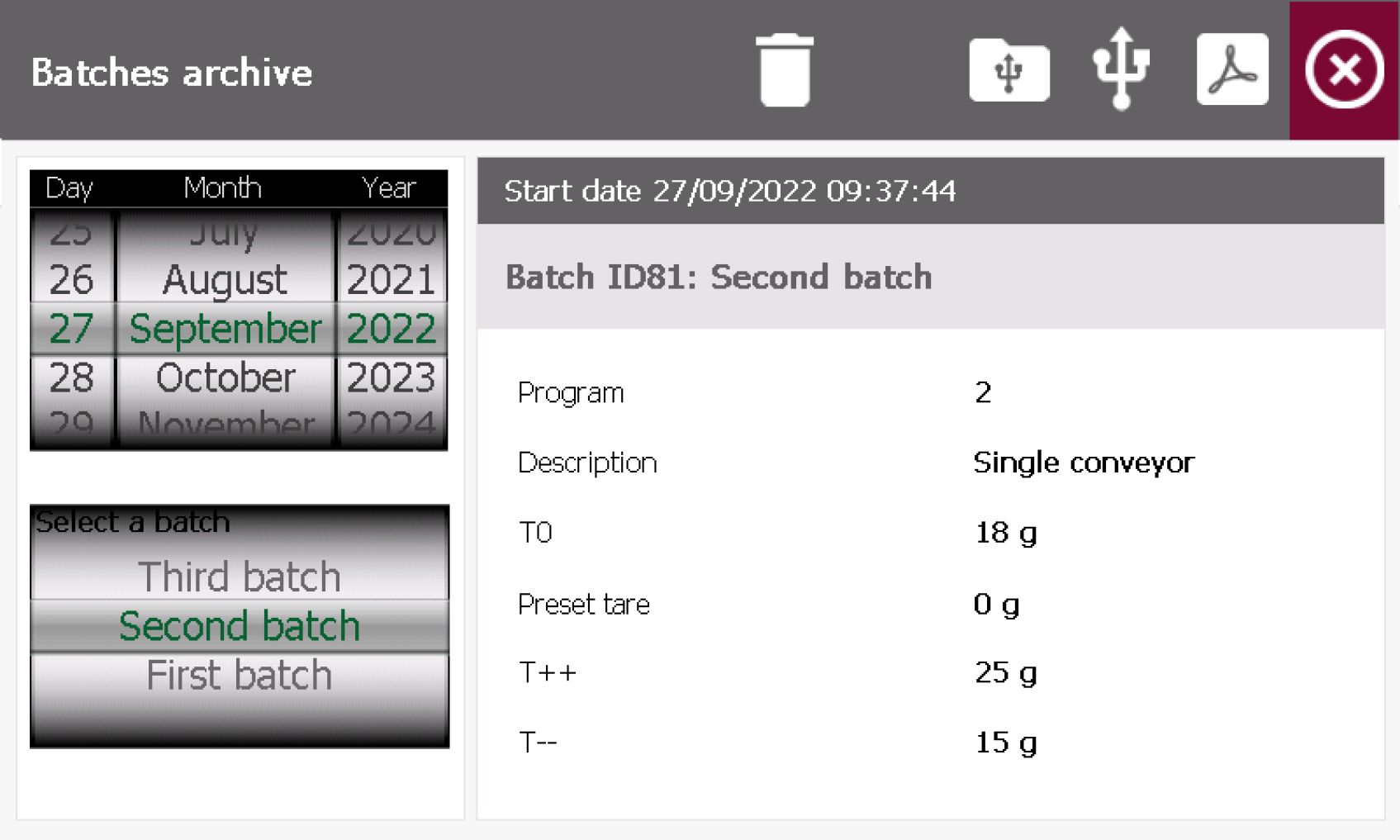

Touchscreen

It's called Touchscreen, and it only takes 5 screen touches to set any of the various functions of the machine.

This weighing management software can store up to 10,000 programs in its internal database for 6 months and is equipped with diagnostics and guidance for problem resolution in case of anomalies and alarms detected by the system.

All weighing data can be manually exported in PDF format using a USB key.

In addition, other software packages can be added, providing access to advanced reporting, complete traceability, and line efficiency monitoring. These packages also offer next-generation features for remote control of all Nemesis checkweighers, weigh price labelers and automated weighing systems.

NEMESIS Data Manager

Pre-set on each machine, it is a system software that can be activated with the insertion of a license code.

It enhances the machine data storage capabilities (up to 24 months) and allows for automatic download of reports for all batches to a USB stick in PDF and CSV format. This can be done in real-time via Ethernet, creating an SQL Server database.

In the latter case, the installation of NEMESIS Analytics is also required.

NEMESIS Analytics

It is a Windows©️ software that enables complete batch reporting and product traceability, along with line efficiency monitoring, for a network of up to 16 connected machines with a single license. This weighing software can be easily installed on your PC with a USB key. NEMESIS Analytics extracts real-time advanced batch reports, including statistics and graphs, from the SQL Server database created by NEMESIS Data Manager, in PDF, CSV, and XML formats.

NEMESIS Analytics is your personal IT manager, making database analysis simple and fast like never before.

By collecting data from each machine, you can easily compare the production efficiency of each line and improve your quality and efficiency.

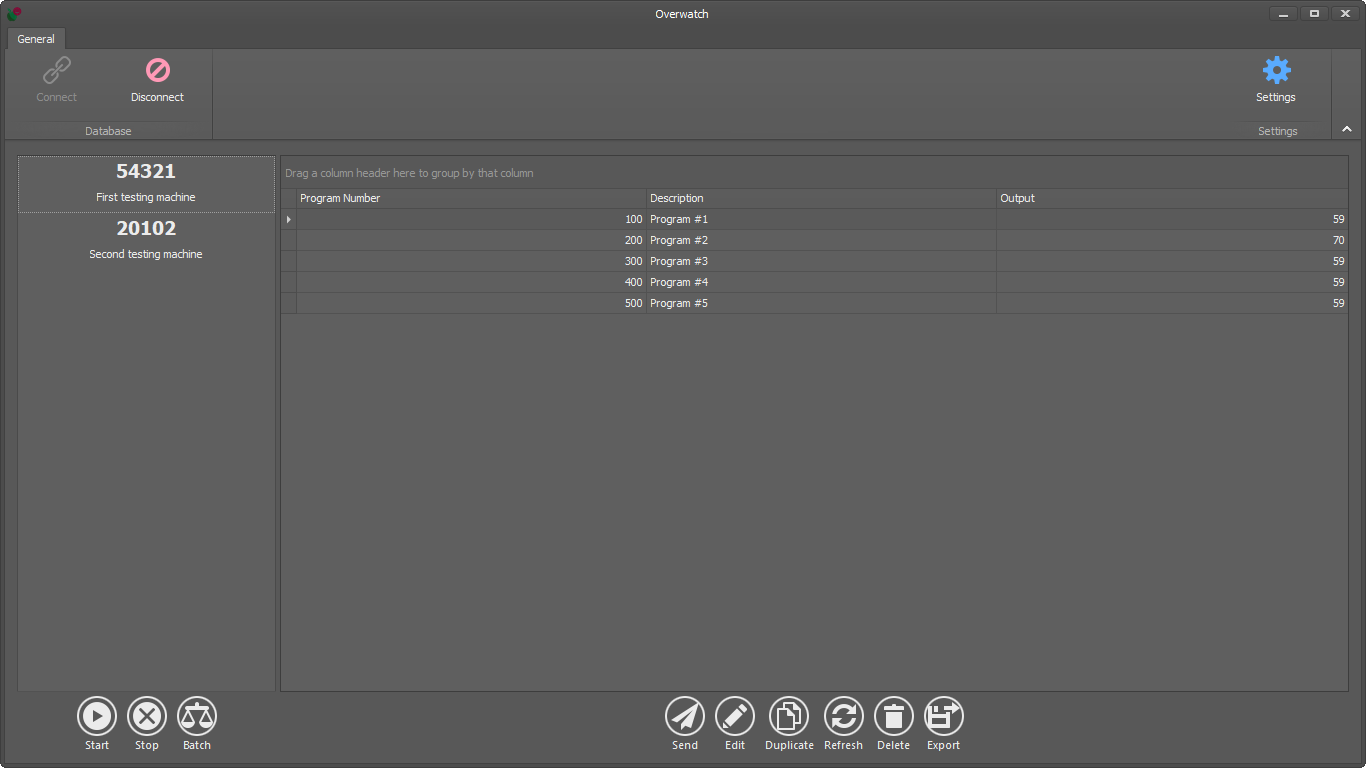

NEMESIS Overwatch

It is a PC software that is installed through a USB key and becomes your remote command console for all connected machines (up to 16). With Overwatch, you can remotely control the start and stop of the machines, set up existing programs (PLUs), create new ones, and launch system backup and restore when needed.

Due to its features, it is considered Industry 4.0 technology, and its installation makes the entire system eligible for government grants and other financial assistance tools.

NEMESIS Proactive Feedback

With Proactive Feedback, your NEMESIS selector becomes a real tool for monitoring and managing the production phase. It progressively monitors the weight trends of the products in the batch as they are measured. Based on this data, it allows for the real-time control of the dosing machine, installed upstream in the line.

If an increase in the average weights is detected, the selector will communicate with the filler to proportionally reduce the filling. Conversely, in the case of repeated underweights compared to the target weight, a command to increase the filling will be sent, again in proportion.

This real-time control enables significant savings, both in terms of waste reduction and the streamlining of the entire production process, drastically reducing the number of non-conformities and the associated costs of managing waste.